Protect Life Science by monitoring & recording temperatures in transit

Discover our brand new and exclusive product range of temperature indicators, designed to reduce reship and replacement rates by up to 30-50%.

Discover our brand new and exclusive product range of temperature indicators, designed to reduce reship and replacement rates by up to 30-50%.

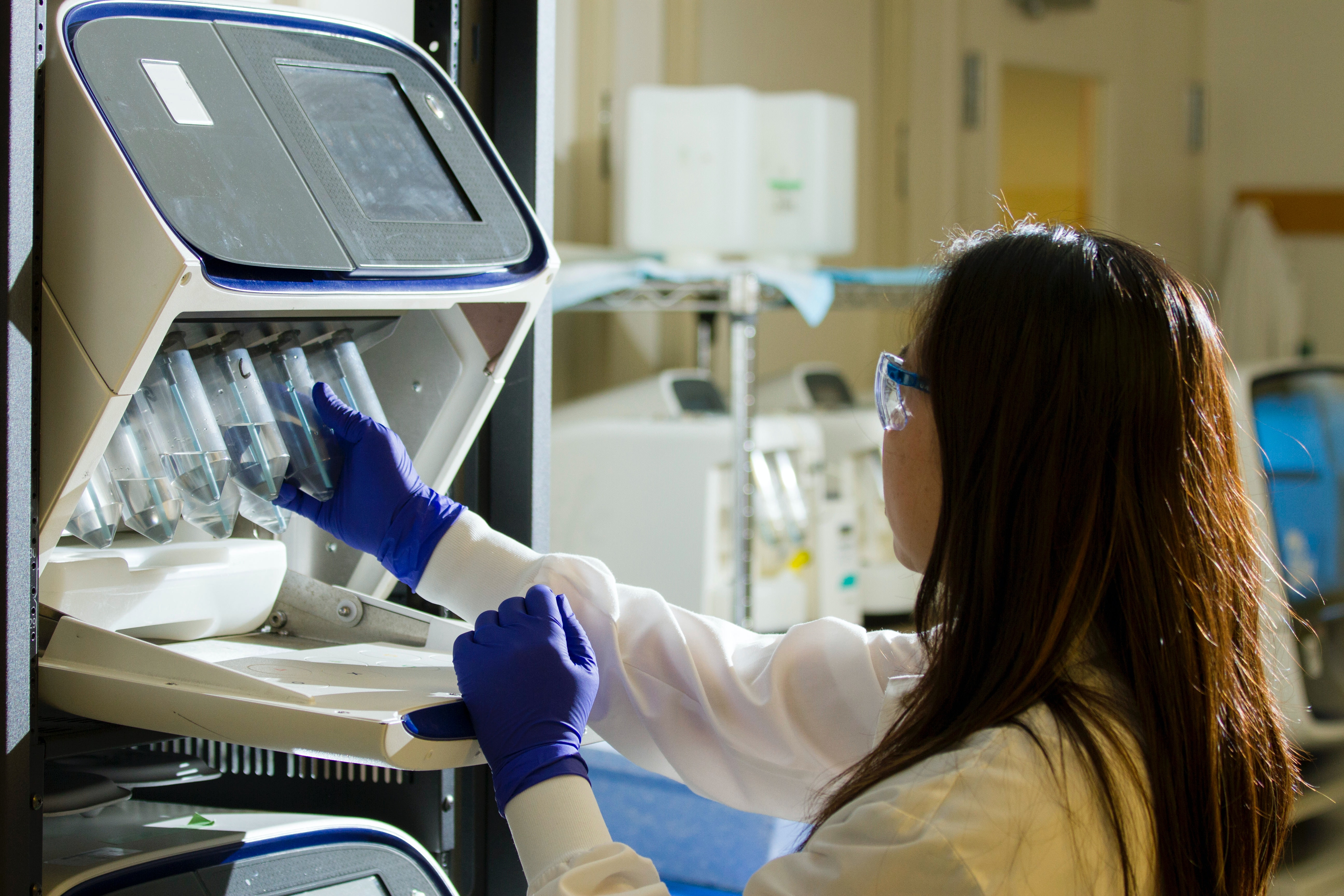

Blood, medicine and vaccines can be susceptible to temperature damage in the cold chain. With an increasing growth in the number of temperature-controlled healthcare products being shipped, it’s never been more important for pharmacies, hospitals and laboratories to monitor their shipments.

The knowledge that cargo is actively being monitored deters bad handling behaviour by supply chain participants.

Connected monitoring enables real-time damage detection so costs are minimized, and responsible parties are held accountable.

Analytics provided by shipment monitoring enable the diagnosis and elimination of pain points within the supply chain.

A single-use, ascending time-temperature indicator which alerts users to cumulative time of the exposure to unacceptable temperature conditions. The indicator is field armable with pull tab.

Descending, single-use temperature indicator that provides accurate, irreversible evidence if a product has experienced unacceptably low temperatures. The indicator turns from white to magenta when the temperature goes below a predetermined threshold of 0°C / 32°F or 2°C / 36°F.

Provides a clear visual indication that products have been exposed to descending temperatures with irreversible colour change from green to red.

We can provide custom products that monitor the temperatures in transit you require. Get in touch with our expert team at Swiftpak today.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

In the pharmaceutical industry, maintaining temperatures during shipment is vital. Here's how WarmMark can be used to protect the health and safety of consumers worldwide.

With so many vaccine doses being shipped to pharmacies, physicians’ offices, and hospitals globally, there is a risk of mishaps. Discover how temperature indicators were used to protect flu vaccines here.

A cost-effective solution was needed that could track individual product damage and alert supply chain managers of the damage before the product moves further along in the supply chain.

We don't stop at protecting life science products. Our further transit monitoring range covers everything you need to reduce reship and replacement rates. Why not explore our impact and tilt monitoring solutions right here.

When it comes to packaging, there are many hurdles the pharmaceutical and chemical industry have to overcome. There’s sustainability, health and safety requirements, labelling, UK laws and lots more to think about. Discover our top packaging tips for the Pharmaceutical and Chemical industry.

When looking to store and transport pharmaceutical products safely, you first need to think about what packaging is required in order to deliver a successful solution. This depends on what product you’re dealing with.

Pharmaceutical packaging plays a number of important roles when shipping sensitive and tightly regulated products. Not only must it protect the contents from physical damage, but should ensure zero alteration is made to the chemical composition.